Aerospace & Defence

We support national and international companies operating in the Aerospace & Defense sectors, offering advanced technologies and cutting-edge materials to meet the most complex needs.

Additive Manufacturing: Advanced Solutions

for Companies of the Future

Born as a rapid prototyping technology, Additive Manufacturing has rapidly evolved into a strategic solution for large-scale industrial production. Today, it represents a fundamental pillar for the future of industry, offering high performance, consistent quality, and operational safety even in the most complex and critical environments.

A concrete response to the challenges of the most demanding sectors, where reliability, innovation, and certified quality are essential requirements.

Aerospace: Innovation that goes beyond borders

Since the beginning, the aerospace sector has represented the pinnacle of human technological innovation. Pushing beyond known boundaries, it has always required the use of cutting-edge materials, processes, and technologies capable of surpassing previously untapped limits. A single question guides this ongoing evolution: how far can we go?

Industrial-grade additive manufacturing has responded to this challenge, evolving in every aspect to support the development of new frontiers previously only imagined. Today, thanks to industrial 3D printing systems from Stratasys and Formlabs, it is possible to design and produce aerospace components with complex geometries, high-performance materials, and unprecedented precision.

Aerospace Applications

Additive manufacturing’s applications in the aerospace industry are broad and strategic. They range from functional prototyping—ideal for design and functional testing during the development phase—to serial production of components intended for commercial and operational applications.

Below are some practical examples of the use of advanced additive technologies.

Verification Systems

Wind tunnel prototype: made using 3D printing solutions, it allows for aerodynamic verification and dynamic stress testing on the wings of unmanned aircraft.

Control Systems

Assembly inspection tool: used for the dimensional and functional inspection of internal components of a sub-orbital aircraft (ABS-M3I), it guarantees precision and repeatability in the most delicate phases of the production process.

Production Support Systems

Composite molds: Made from ULTEM™ 1010 and ULTEM™ 9085, they enable short-run production of complex, lightweight parts while maintaining high mechanical and thermal performance, ideal for the needs of the aerospace industry.

Defence

Defence is the ideal context in which SolidWorld Group can maximize the strengths of Additive Manufacturing: extreme customization, on-demand production, reduced procurement times, and logistics optimization.

A highly qualified team, driven by passion and consolidated expertise, capable of offering high-value solutions, makes SolidWorld Group a key player in the market. In a sector where quality is essential and performance is crucial, we support the Armed Forces to ensure efficiency, reliability, and operational readiness.

In the Defense sector, industrial additive manufacturing represents an unprecedented revolution in terms of operational flexibility, high performance, and rapid response.

Technologies that accept no compromise, designed to address the most critical challenges with maximum reliability.

Divisions Components Developments

Armaments Division

Additive manufacturing plays a strategic role in the design and development of weapons. Among the most significant applications are functional prototypes in high-performance polymers, created using various printing technologies to optimize the ergonomics, balance, and function of firearm mechanisms.

Aeronautics Division

The global geopolitical landscape demands rapid, efficient, and scalable technological solutions. Industrial 3D printing fully meets these needs, offering lightweight, high-performance, and certified components suitable for use on both manned and unmanned aircraft.

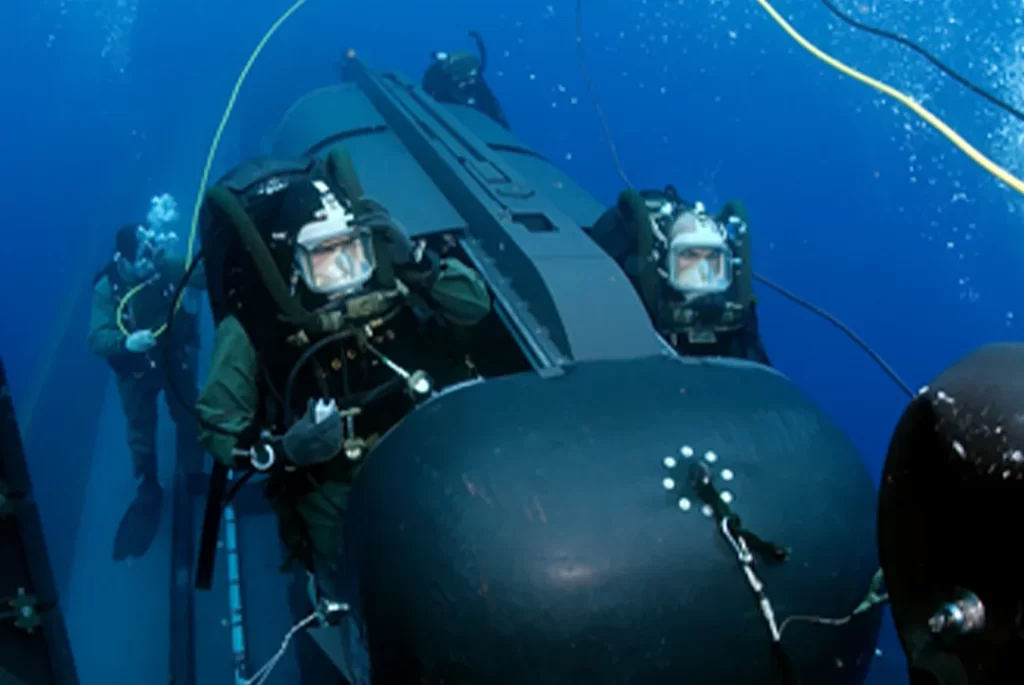

Naval Division

Thanks to the use of certified, high-performance materials, we design elements intended for underwater systems and immersed devices, guaranteeing durability and precision, even in environments with maximum exposure to humidity, pressure, and corrosive agents, and resistant to extreme environmental conditions.

Land Vehicles Division

The integration of 3D printing on land vehicles, including remote-controlled vehicles, enables the rapid insertion of countermeasure systems, sensors, custom protections, and lightweight structures while maintaining design flexibility and rapid development.

Electronics and Countermeasures Division

The use of materials such as ULTEM™, NYLON 12 CF, and other advanced composites, combined with industrial 3D printing, enables the creation of lightweight, robust, and custom-made electronic and structural components.

Thanks to our team’s experience, we produce components for radar systems, electronic countermeasures, and interception devices, where reliability, rapid integration, and precision are key factors.

Tomorrow is now!

Find out our solutions and request a consultation to turn your contribution into concrete action.